SRU Reliability

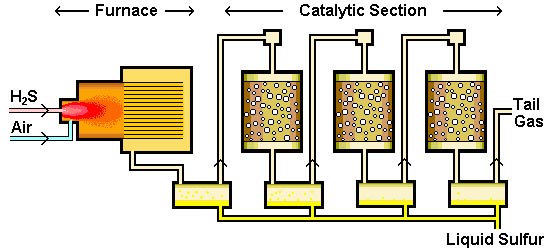

The Sulfur Recovery Unit (SRU) is an extremely important unit in the Refinery or Gas Plant. Without it, there would be harsh adverse environmental consequences including severe acid rain, as well as lethal ground level SO2 toxicity. The Claus plant is in place to convert H2S to valuable elemental sulfur and to minimize the amount of sulfur compounds released to the atmosphere. Many SRUs also now have a Tail Gas Cleanup Unit (TGCU) following the Claus Plant in order to recover even more sulfur and further minimize emissions.

Learn more about the Sulfur Recovery Process.

Sign-up to receive SRE’s Newsletter.

REGULATORY GUIDELINES

As the international community continues to strive towards minimizing our impact on the environment, the regulatory bodies have to impose higher minimum overall recovery efficiencies from the SRU. Not only do the day-to-day SRU operations need to include optimization and reliability to meet these recovery efficiencies, even guidelines during upset conditions (including flaring) are becoming much more stringent. The bottom line is that the SRU must be both reliable and able to achieve the minimum overall recovery efficiency required on a day-to-day and long-term basis.

Learn more about SRE’s On-Site Services & Solutions.

Contact us now for a Free Quotation.

THIRD PARTY ON-SITE SRU PERFORMANCE EVALUATION

Regular third party on-site SRU performance testing should be conducted once per year, at a minimum. Quarterly or semi-annual testing has been proven to be very effective in that problem areas are detected early and can be resolved, with far lesser consequences than finding out later when an emergency or unscheduled shutdown must be performed. Thermally, emergency shutdowns are very stressful on the equipment in the SRU, potentially unsafe, and can limit the facility’s production rates.

SRU START-UPS AND SHUTDOWNS

SRU start-ups and shutdowns are difficult and dangerous procedures that have the potential of causing serious damage to the SRU if not conducted properly. It is very important to have clear and concise SOPs in place, such that all personnel are clear on what is to be accomplished and how it can be performed safely and efficiently. Shutdowns are particularly difficult due to the threat of serious sulfur fires in the Catalytic Reactors. Any ‘free oxygen’ that is allowed to reach a Reactor during the early stages of a shutdown will result in a sulfur fire, which in the worst case can destroy the catalyst and the internals of the bed. Burning fuel gas in the Reaction Furnace must be conducted carefully and will include good control of the air-to-fuel gas flow ratio, inert gas for ‘tempering’ the Reaction Furnace flame, and combustion gas analysis that will allow for the evaluation of the fuel gas burn stoichiometry at any given time. Third party assistance is highly recommended due to the experience factor and the critical feedback that the combustion gas compositional analysis provides.

Contact us with any Procedural Questions or learn more about SRE’s SRU Shutdown or Start-up Assistance.

THE VIRTUAL SRU

SRE has partnered with Virtual Materials Group (VMG), allowing SRE to use the powerful VMG Sulfur Plant simulation software in-field (VMGSim® ). Using years of accumulated SRE sulfur unit data, our team is able to accurately model any given SRU. In conjunction with our field results, the models provide important process values such as Reaction Furnace adiabatic temperature, Reactor bed dewpoints, and catalyst activity.

Contact us now to learn more about the creation of both Steady-State and Dynamic models of your SRU!

OPERATIONS AND MANAGEMENT KNOWLEDGE BASE

A knowledgeable Operating team is key in ensuring the reliability of your SRU. The SRU is ‘unforgiving’ in the sense that when things go wrong, it happens very quickly and with serious consequences. It is therefore very important that a facility has very experienced Operators and an excellent training course for new or inexperienced Operators. The training program should include ‘hands on’ control room/board training and classroom training. An Operator round/check schedule should include everything that has been mentioned thus far.

Learn more about SRE’s tailored SRU Training.

Learn more about SRE’s tailored Amine Unit Training.

Contact us now for a Free On-Site Training Quotation.

Learn more about SRE’s On-Site Services & Solutions.

Management must also be aware of all the above issues, such that appropriate measures are taken to ensure that optimal sulfur recovery efficiencies are achieved on a day-to-day basis and that reliability continues to improve. The operating budget for an SRU must take all of this into account or the consequences can be extremely dire to personnel, the environment, and the gross revenue of the facility.